It has been used primarily for transformer cores magnetic shielding ground fault circuit interrupters tape wound toroids and laminations operating at very low magnetic.

Relative permeability of steel laminations.

Our high speed tooling offers a low cost alternative to maufacturers with moderate to high volume stamping requirements.

Electrical steel lamination steel silicon electrical steel silicon steel relay steel transformer steel is a special steel tailored to produce specific magnetic properties.

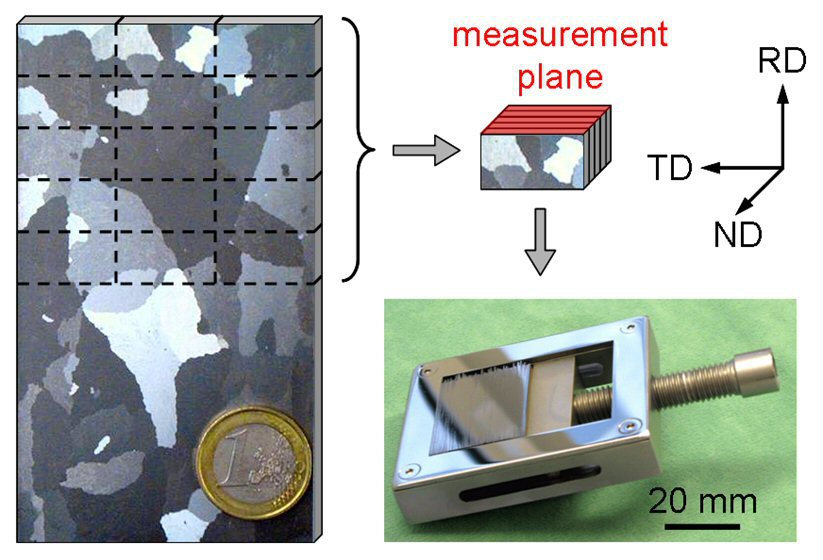

Laminations mechanical cutting causes up to 35 higher iron loss density and 63 lower permeability compared to standard epstein strips 30 mm wide.

Cartech hymu 80 alloy is a nonoriented 80 nickel iron molybdenum alloy with extremely high initial permeability and maximum permeability with minimum hysteresis loss.

This is achieved by various hot and cold rolling stages to produce textured sheets known as grain oriented silicon steel with the 001 direction in the length of the lamination.

This product group consists primarily of 006 029 low carbon and silicon alloy steels.

The qualities of the carlite 3 coating are best maintained or enhanced when stress relief annealing is conducted in an atmosphere that is neutral or slightly oxidizing to iron.

A magnetic core is a piece of magnetic material with a high magnetic permeability used to confine and guide magnetic fields in electrical electromechanical and magnetic devices such as electromagnets transformers electric motors generators inductors magnetic recording heads and magnetic assemblies it is made of ferromagnetic metal such as iron or ferrimagnetic compounds such as ferrites.

More detailed information about these two types of steels can be found in the metals handbook.

Electrical steel is usually manufactured in cold rolled strips less than 2 mm thick.

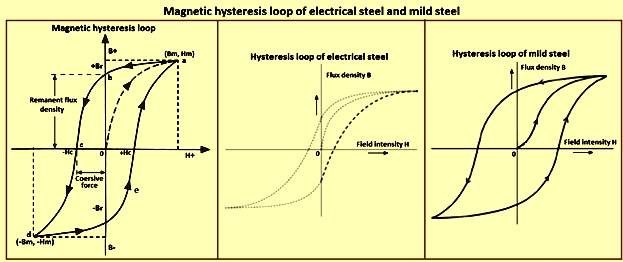

Small hysteresis area resulting in low power loss per cycle low core loss and high permeability.

Steel cores or laminations can usually be removed from the protective atmosphere at 600 700 f 325 375 c without ill effect.

Small hysteresis area resulting in low power loss per cycle low core loss and high permeability.

Custom steel laminations represent over 50 of all sko die stampings.

Both are non oriented steel grades.

Electrical steel lamination steel silicon electrical steel silicon steel relay steel transformer steel is an iron alloy tailored to produce specific magnetic properties.

The corresponding degradation for laser cut laminations is 65 iron loss density increase and 65 per meability drop.

There are two types of electrical steels used for rotor laminations semi processed and fully processed.

Our average lead times on new tooling range from 10 12 weeks.

Material of lower thickness but with the same si content shows lower.

The magnetic properties namely the iron losses and the relative permeability of sife electrical steel laminations after mechanical and laser cutting are studied.

Electrical steel is usually manufactured in cold rolled strips less than 2 mm thick.